Old Dog, New Tricks: 3D Printing

We recently took our first dabble into the world of 3D printing. If you are not familiar with 3D printing, imagine your printer at work not only going back and forth as it prints out lines of text, but also "printing" layers upon previous layers making the text 3D. This is why 3D printing is also called "additive manufacturing." So you could theoretically print any 3D object from an electronic file. Needless to say we've been watching the space excitedly because, not only could it significantly cut down on materials waste, but also any of our designs could be printed by whomever has the right file, anywhere in the world...in theory.

Perhaps fortunately, the reality of 3D printing is not up to that scale yet. Most printers simply aren't big enough to print a chair, for example, and the costs to do so compared to current fabrication convention would be prohibitive. However, it is very useful, and fun, for small scale pieces, parts and prototypes.

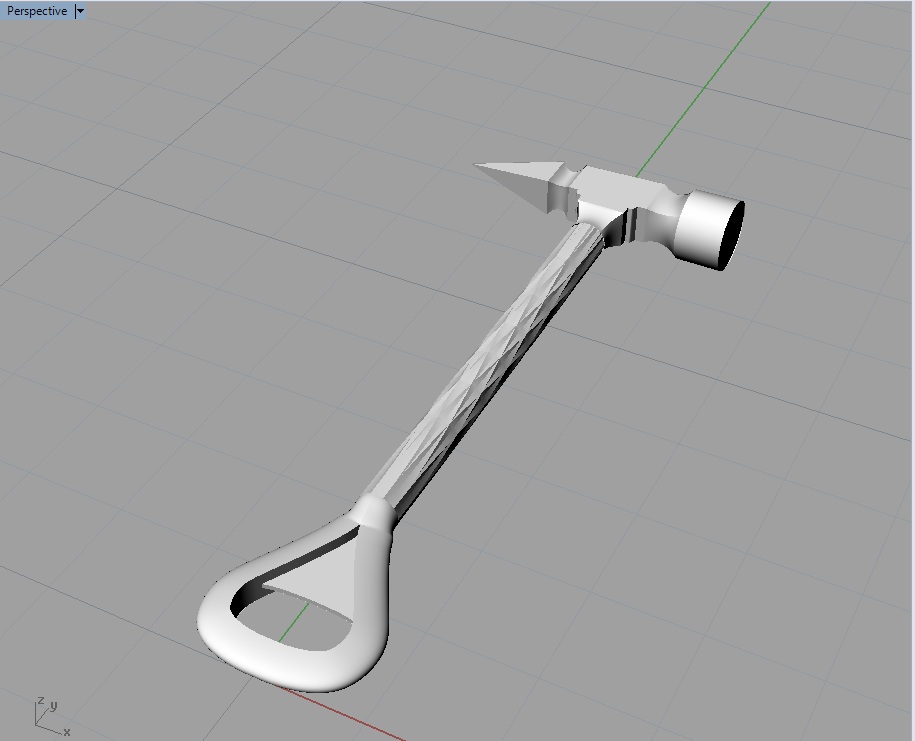

Inspired by a vintage bar-tool, we designed one electronically with a ice pick, mallet, and bottle opener with a patterned grip. Once the file was complete and the design was ready, we uploaded it to Shapeways. Shapeways is basically a 3D printing outsource firm - we don't have our own 3D printer, so we upload a file on their website, they immediately tell us if the file is printable as well as the costs to do so in various materials. We chose to print our prototype in both a grey finished steel and a hardened plastic. Then, Shapeways shipped them both to us in about 1 - 2 weeks.

Having the full scale prototype was extremely useful - right away I could see the handle was too long, the gauge of the bottle opener neck too thick and the grip pattern not as detailed as I expected. The plastic one was the same except that we left the handle with no grip pattern. We did this because we could carve the plastic the old fashioned way. So the next step could be hand-carving the plastic 3D printed prototype and then "lost wax" casting the hand-carved/3D printed prototype. And in fact one of the materials offered for printing was castable wax in the event you are ready to skip the hand-carving step.

Currently, this seems to be the way 3D printing will be the most useful to a design firm like us: printing prototypes that we can then cast. The fact that we could in fact print certain items in castable wax was slightly mind-blowing. So metal parts and hardware, frames and more will now be much easier to customize on a project by project basis. But for production pieces, both because of the time required to print and the cost, 3D printing is not there yet it seems. Also, I am not sure how useful it will be for printing small scale prototypes of custom pieces for clients - I'm not entirely convinced how useful today's client would find a miniature, single material, version of their project and they certainly won't be thrilled by the added time they require. Prototypes may be useful for production pieces as we develop them, however full-scale prototypes seem like they will remain more useful. But we will see - it is fun and invigorating to have another tool for the design process. And like most tools, a year or 10 from now, we'll probably be using it in a number of different ways.

This vintage inspiration piece.

A 3D perspective view of the bar-tool design in Rhino

The metal and plastic bar-tool prototypes.

Most importantly - the prototype works!